"Wheelerguy" (wheelerguy)

"Wheelerguy" (wheelerguy)

10/13/2018 at 10:45 • Filed to: jet fighter, fighter plane, LEGO

2

2

6

6

"Wheelerguy" (wheelerguy)

"Wheelerguy" (wheelerguy)

10/13/2018 at 10:45 • Filed to: jet fighter, fighter plane, LEGO |  2 2

|  6 6 |

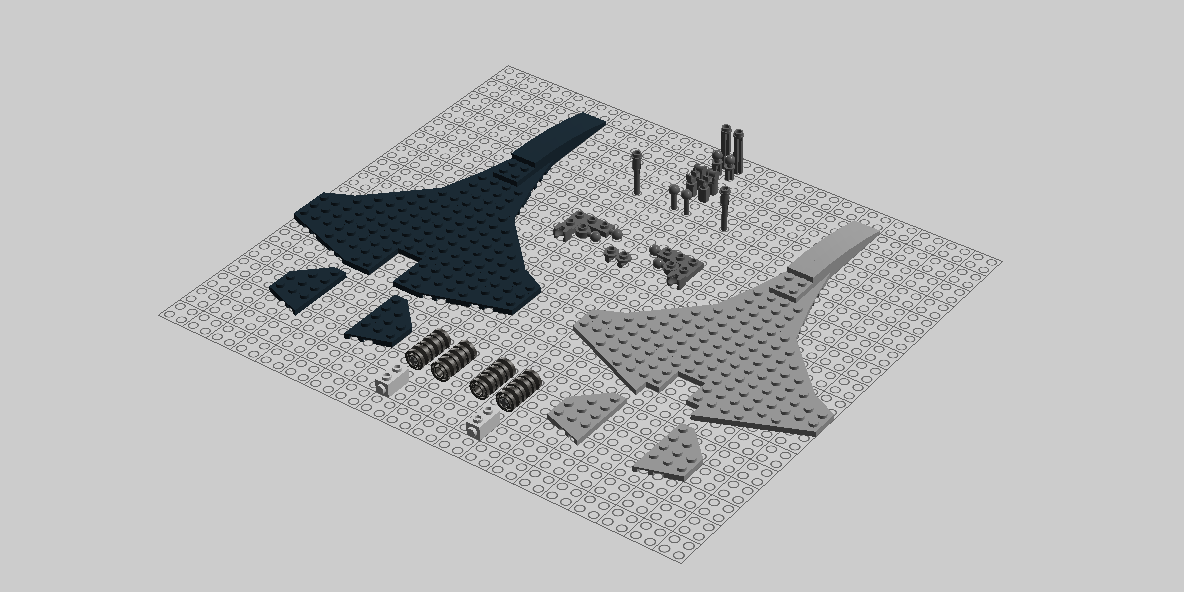

Here’s the puzzle: mount the exhaust (shiny grey pieces) such that I can give it thrust vectoring capability. The biggest challenge is making sure the exhaust is right in line with the plates of the tail while still being able to move them as freely as possible.

Maxima Speed

> Wheelerguy

Maxima Speed

> Wheelerguy

10/13/2018 at 10:56 |

|

Ive heard of this program but never downloaded it. Im doing that now. Im pretty excited to be honest. Also I would love to help but really have no clue what kinds of parts they have these days.

Wheelerguy

> Maxima Speed

Wheelerguy

> Maxima Speed

10/13/2018 at 11:05 |

|

There are equally powerful or more powerful programs like LDraw or LeoCAD, but this indeed is adequate for most building work, and can be paired with rendering software like Bluerender and POV-Ray.

Jayhawk Jake

> Wheelerguy

Jayhawk Jake

> Wheelerguy

10/13/2018 at 12:32 |

|

Use the little ‘claw’ pieces. Should be grippy enough to stay in one place but still allow moving up and down.

Alternatively look up the Bugatti’s gear selector and drive selectors, they have some features you might be able to work though it’s probably beyond this scale

SHARPSPEED

> Wheelerguy

SHARPSPEED

> Wheelerguy

10/13/2018 at 17:25 |

|

Some 1/1 hinge pieces and a jumper plate, maybe?

Wheelerguy

> SHARPSPEED

Wheelerguy

> SHARPSPEED

10/13/2018 at 23:21 |

|

T he problem isn’t really mounting them per se so much as it is mounting them while still able to make the nozzles swivel in three dimensions. The ball joints then to mount in a tricky way. I was thinking universal joint, but that’s hard to implement and looks nothing like an engine.

Lee

> Wheelerguy

Lee

> Wheelerguy

10/15/2018 at 16:54 |

|

The most straight-f or ward way to do this is by running something like a rigid flex hose or a bar through your engine and out the e nd where you would like the engine to hinge. Have it poke out just a little (it will have the effect of creating a male receiver) then place a hollow-stud single round plate on top of that. The rigid hose/bar will establish a very tight connection with the hole in the hollow stud- now, place a 1x1 top clip on top of that hollow stud. This will give you a hinge point at the inboard end of your engine, then you can use that clip to attach to any plate modified with a bar and you will now have an engine you can point up or down from that hinge point.

I think that Bricklink’s new Studio 2.0 will allow you to insert bars or flex hose, but this may be something you need to do IRL. I have used this technique for other things like creating custom axle mounts for wheels on my cars, or creating a ‘core’ for tiny scale robot arms. This type of technique was also used on the Lego Ideas Exo Suit .

Let me know if you have any other questions, and you can see some of those things at work @PleaseYesPlease on flickr. Much Lego car- ner ding there :)